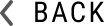

OSHA's Process Safety Management Standard: Is Your Facility Affected?

It's no secret that OSHA has been busy when it comes to monitoring facilities with highly hazardous chemicals (HHCs). Since 2010, OSHA has issued more than 69 enforcement cases regarding Process Safety Management (PSM), and a recent safety and health fine was just issued for $264,000. The problem is, many organizations don't understand OSHA's PSM standard or realize if it even applies to them. Read below to learn all about the Process Safety Management standard and find out whether or not the rule is applicable to your facility.

It's no secret that OSHA has been busy when it comes to monitoring facilities with highly hazardous chemicals (HHCs). Since 2010, OSHA has issued more than 69 enforcement cases regarding Process Safety Management (PSM), and a recent safety and health fine was just issued for $264,000. The problem is, many organizations don't understand OSHA's PSM standard or realize if it even applies to them. Read below to learn all about the Process Safety Management standard and find out whether or not the rule is applicable to your facility.

Why Did OSHA Develop PSM?

In 1991, to help ensure safe and healthy workplaces, OSHA issued the Process Safety Management of Highly Hazardous Chemicals standard (29 CFR 1910.119). This rule contains requirements of the management of hazards associated with processes using HHCs. Additionally, in January 2017, OSHA issued a new National Emphasis Program to further protect workers' health and safety in certain industries that pose high risks to people and the environment.

So, what was OSHA's reasoning for pushing these requirements? OSHA developed PSM due to past industrial disasters resulting in deaths and environmental damages, including:

- Bhopal, India gas leak in 1984

- Phillips explosions and fire in 1989 in Pasadena, TX

- Cincinnati, OH chemical plant explosion in 1990

- Sterlington, LA explosion and fire in 1991

To help minimize these occurrences, PSM was created. PSM aims to prevent the release of toxic, reactic, flammable, and explosive chemicals into the environment.

What Facilities are Covered?

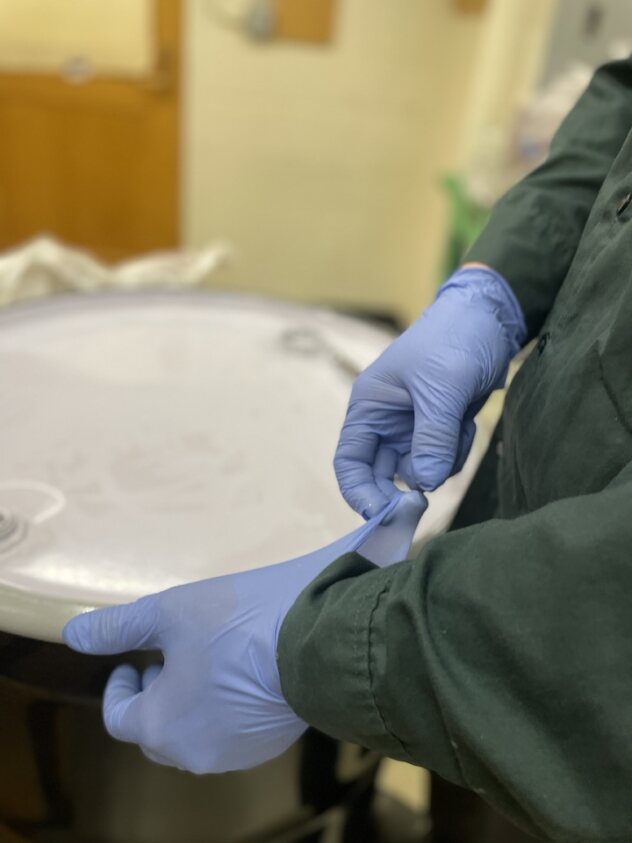

OSHA states that the PSM standard applies to "a process which involves a chemical at or above the specified threshold quantities (TQs) listed in Appendix A of the standard. The Appendix contains a list of toxic and reactive HHCs which present a potential for a catastrophic event at or above the TQ. When evaluating chemicals on the list, it's important to look at the TQ as well as checking and verifying the chemical abstract service number (CAS). This involves the entire chemical inventory, making an appropriate chemical inventory process crutial.

One important interpretation to note is that OSHA uses the phrase "on site in one location" in the standard to mean that the standard applies when a TQ of a HHC exists within an area under the control of an employer or group of affiliated employers. It also applies to any group of vessels that are interconnected or in separate vessels that are close enough in proximity that the HHC could be involved in during a potential catastrophic release.

Types of Industries Included

Any industry that processes chemicals could be included in OSHA's PSM standard. Some examples of these industries include:

- Industrial organics and inorganics

- Paints

- Pharmaceuticals

- Adhesives

- Sealants and fibers

- Petrochemical facilities

- Paper mills

- Food processing with anhydrous ammonia over the TQ

Exclusions

A company is exempt from the requirements of PSM when:

- A TQ of flammable liquids is stored in atmospheric tanks or transferred without the benefit of chilling or refrigeration.

- Hydrocarbon fuels are used solely for workplace consumption as a fuel (e.g. propane used for comfort heating or gasoline for vehicle refueling).

- Fuels are not a part of a process containing another HHC covered by this standard.

If You Are in PSM...

Considering the severity of the consequences that HHCs pose to the environment and the past disasters that have occurred, we only see PSM continuing to become a stronger and stronger regulation. Learn about our chemical inventory management services here. Click the button below to watch our webinar to get up to speed on OSHA's PSM standard, find out how to stay compliant, and learn how to create a PSM program from the ground up!

.png)