Learn how our end-to-end process can overcome all your plastic waste challenges.

.png)

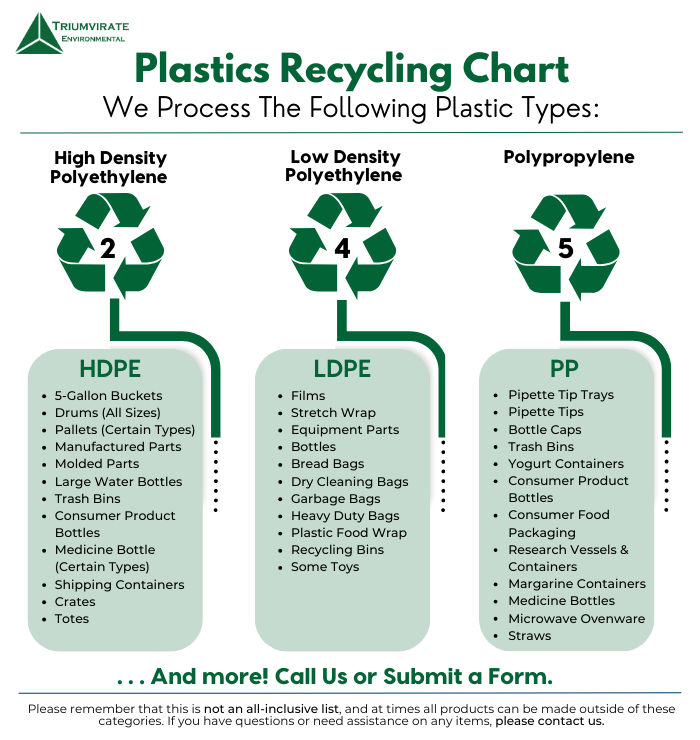

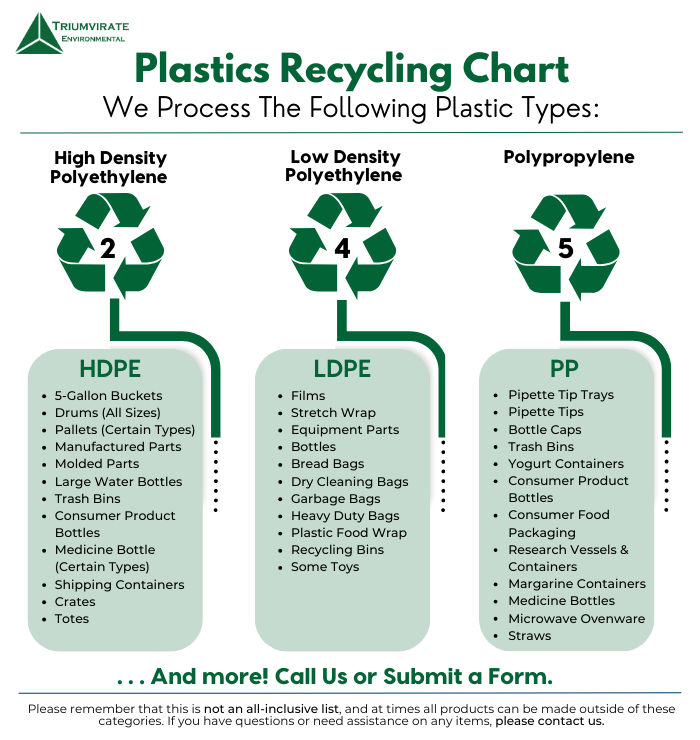

Triumvirate Environmental partners with companies like yours to provide sustainable and cost-effective recycling solutions for various types of plastic waste, such as polyethylene. We acquire various types of polyethylene. including low-density, high-density, and more! Currently, we do not sell plastic.

We divert plastic waste products—that typically are buried in landfills—and recycle them into various forms of plastic lumber. The end products include landscaping components, synthetic turf nailer boards, truck and trailer parts, and pallets. We then provide certificates of recycling and destruction, completing a cycle that saves money for our clients and protects the environment.

Contact us today to learn how your company can benefit from a plastics recycling program.

High-density polyethylene (HDPE) is a robust, rigid plastic commonly used in 5-gallon buckets, totes, drums, and certain types of medicine bottles. It is resistant to chemicals and high temperatures and boasts excellent impact strength and strength-to-weight ratio. These properties make HDPE a versatile material for which recycling processing is easily facilitated.

Low-density polyethylene (LDPE) is a flexible, pliable plastic often found in equipment parts, stretch wraps, recycling bins, and garbage bags; its low density and exceptional moisture barrier make it ideal for many packaging applications. LDPE's reasonable temperature resistance and compatibility with other plastics ensure smooth integration within the recycling process.

Polypropylene (PP) is a versatile plastic used in a wide array of products, including pipette tips and trays, certain medicine bottles, and trash bins. Known for its strength, durability, and chemical resistance, PP is also non-toxic, lightweight, and adaptable—making it a popular choice for various applications. These properties also contribute to its recycling suitability.

Energy Conservation: Recycling plastics for use in new applications is significantly less energy-intensive than producing new plastic.

Waste Reduction: Recycling helps mitigate environmental pollution by diverting plastic waste from landfills.

Greenhouse Gas Emission Reduction: Plastic production from raw materials is associated with greenhouse gas emissions; recycling thus decreases emissions.

Resource Conservation: Recycling conserves natural resources that would otherwise be used to manufacture new plastic.

Triumvirate Environmental’s subsidiary, Best Plastic Lumber U.S. (BestPLUS), is a sustainable plastic lumber manufacturer. It provides durable, low-maintenance recycled plastic lumber to a variety of industries.