How to Make Your Satellite Hazardous Waste Accumulation Areas Work for You

Setting up a series of satellite hazardous waste accumulation areas (SAAs) is a great way to maximize efficiency at your business while helping to cut down on the regulatory red tape associated with a main hazardous waste accumulation area. While the regulatory framework surrounding these areas is less stringent than for a main accumulation area, there are still some important rules surrounding them, but rather than being a nuisance, these can help you to place your SAAs around your facility in the most efficient manner possible. Here are some tips for making sure you get the most out of your SAAs without landing in hot water with the EPA.

Basic Placement Rules

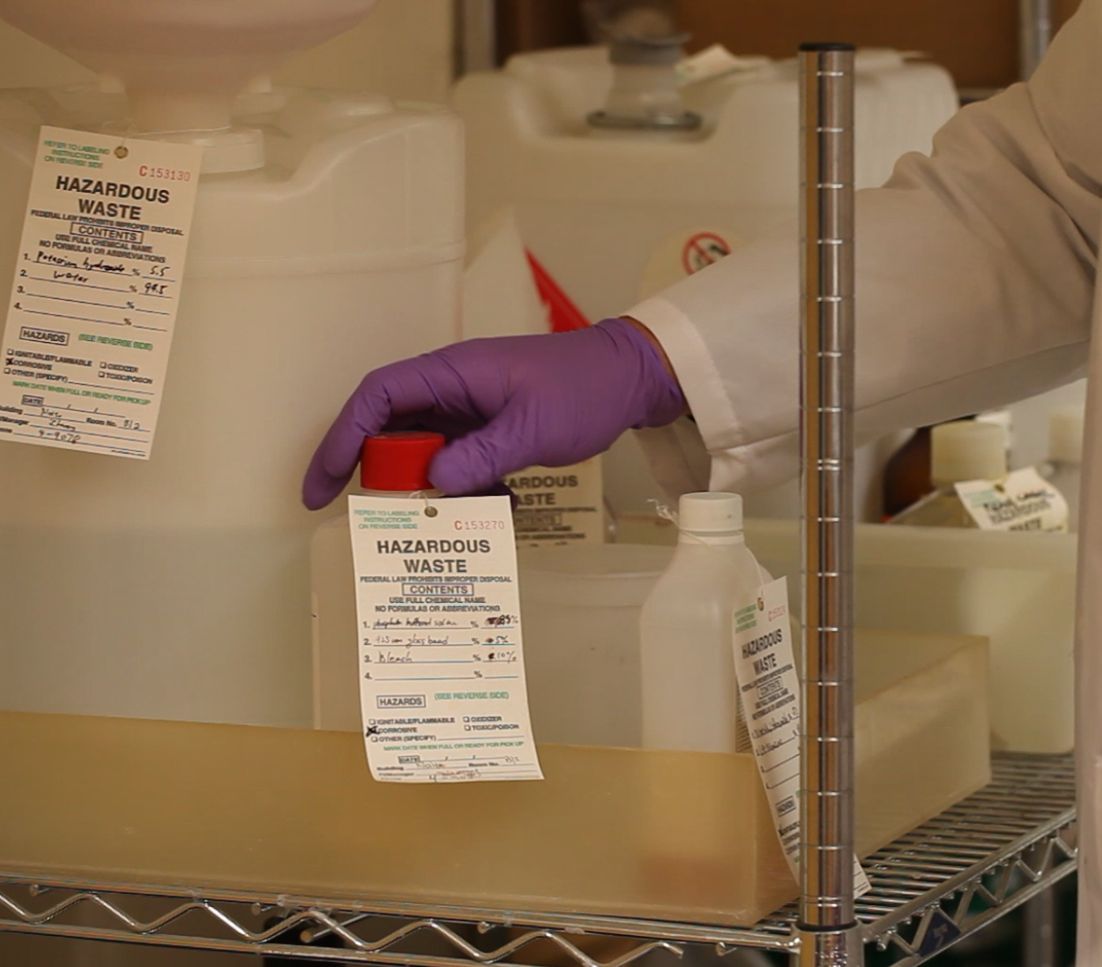

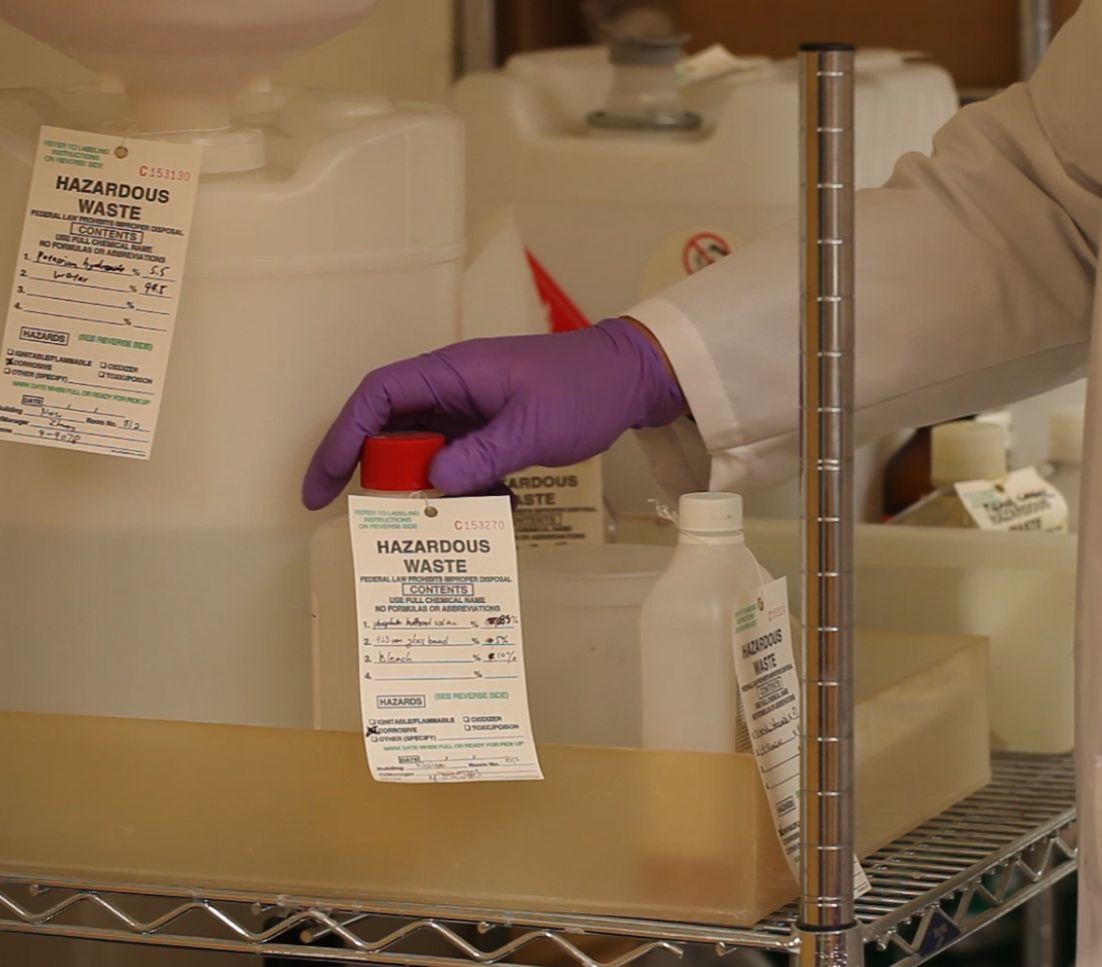

The EPA doesn’t specify many rules for placing SAAs, but there are a couple you should be familiar with. First off, all drums should be on spill decks that allow for 10% of the total container volume or the entire volume of the largest container to be collected, whichever is greater. It should also be noted that your containers should be impervious to corrosion from the waste therein (to check this, consult a corrosion guide, which is often available from your chemical supplier). Second, these spill decks should be accessible from all sides for the sake of emergency response personnel in the event of a fire, so you can’t just bury spill decks in every corner of your building. Third, your SAAs should be at or near the point where the waste itself is generated, and they have to be on the property of the generator of the waste, per EPA regulations.

Integrating Your SAAs Into Your Facility’s Floor Plan

Now that we have a firm handle on what the EPA specifies about placing your SAAs, let’s get into the nitty gritty of making these spaces work for you. Setting up these areas where they won’t get in the way means mentally or physically doing a run through of your facility’s daily operations and mapping out which areas need to stay clear and which can harbor an SAA. It helps to draw arrows and equipment movement on a floor plan to get an idea of high and low traffic areas, and therefore where best to place your SAAs so as to serve high traffic areas without blocking them.

Examples

- If you want to cut down on the number of forklift trips to and from where abrasive blasting takes place, for example, then you’ll not only need to make the SAA easily accessible for a forklift, but also somewhere along the route that a forklift would typically take to transport waste. This is where drawing out a dynamic floor plan helps greatly, so you can see where exactly to intersect and shorten a forklift’s trips around your facility.

- If you’re planning on keeping smaller containers at your SAAs, like small buckets akin to sharps containers, then you have some more breathing room for placement. In these cases, it’s usually advantageous to put these areas as close to the workspace using them as possible.

For more assistance maximizing your SAA's, check out our related services!