How Plastic Lumber Production Helps Divert Waste from Landfills

Sustainability continues to be top of mind for organizations across all industries. Working towards zero waste to landfill, for example, was among the most prevalent trends cited in 2021. Zero waste to landfill refers to an initiative in which businesses divert their generated waste streams away from landfill and instead reuse, recycle, compost, or convert the waste into energy.

When executed effectively, employing waste diversion strategies to reduce the amount of waste your company sends to landfill can reduce your operation's negative environmental impacts, improve your corporate reputation, save money on expensive waste treatment options, and even generate income if your waste streams have reusable value.

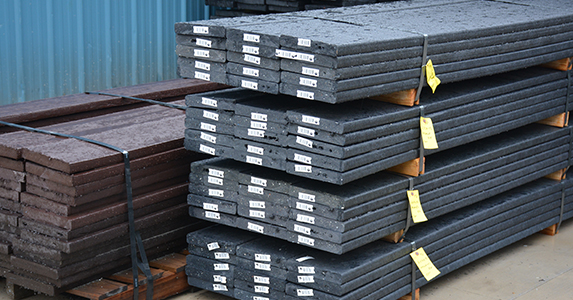

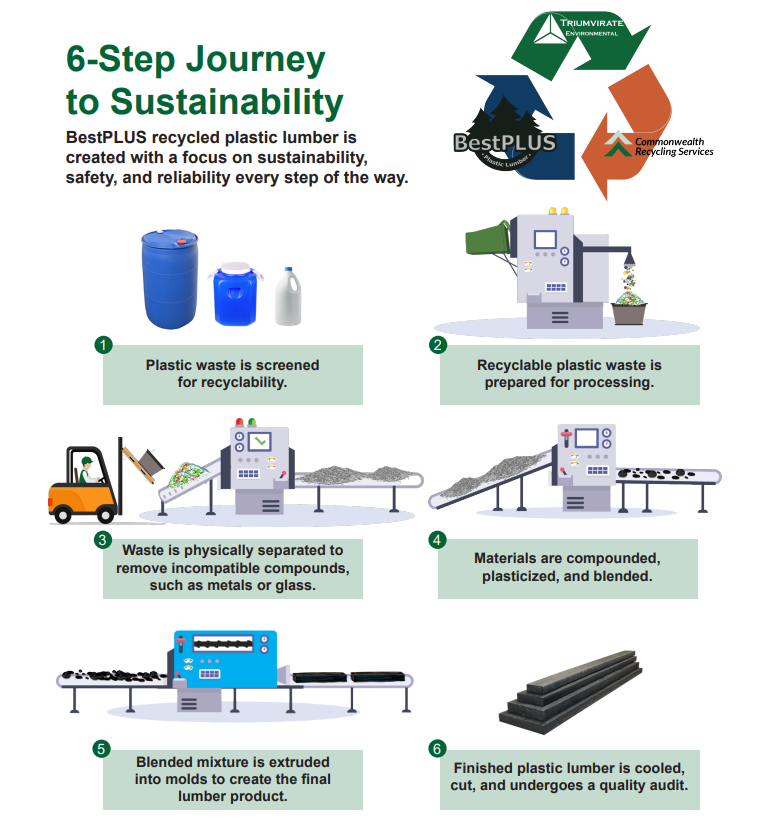

How organizations approach working towards their zero waste initiatives depends on the nature of their operations, budgetary limitations, regulatory requirements, and current waste treatment methods, among other factors. A common challenge is determining what waste streams can be recycled and how, particularly when materials are made up of a variety of components such as metals, mixed plastics, non-recyclable materials, and more. Triumvirate Environmental's subsidiaries, Commonwealth Recycling of Pennsylvania and BestPLUS Plastic Lumber, work to divert a significant portion of mixed plastic waste from landfills by recycling it and turning it into plastic lumber. BestPLUS plastic lumber is sustainable, low-maintenance, and long-lasting, designed for a variety of landscaping applications.

The plastic lumber manufacturing process can be broken up into 6 steps:

- Waste screening

- Material preparation

- Physical separation

- Processing & compounding

- Molding & extrusion

- Board finishing & quality assurance

To learn more about Triumvirate Environmental's recycling solutions and sustainable approach to waste disposal, as well as how to determine whether or not your company's waste streams are a good fit for our recycled plastic lumber manufacturing process, watch the recording of our recent webinar, Challenging the Plastics Recycling Model, or call (617) 715-8997 to speak to an expert.