F006: Double Check the Rule to Ensure Compliance

The RCRA F006 rule provides a list of exceptions to wastewater treatment sludge from the electroplating process (40 CFR 260.11).

The RCRA F006 rule provides a list of exceptions to wastewater treatment sludge from the electroplating process (40 CFR 260.11).

The list exempts sulfuric acid anodizing or tin-plating of steel, among other chemicals. This rule does a great job of explaining what is not F006 waste, but is pretty vague in regards to what is indeed covered under the F006 rule.

Larger definitions of electroplating include any process that coats a metal in another metal, usually by chemical and electrical means according to the EPA definition. This seems straightforward enough, but this broad definition of electroplating might cover more processes than you think. Many businesses in the metal treating, finishing, and processing fields are subject to this regulation, even those that might not explicitly be involved in the electroplating process by common definitions.

Overlooking or ignoring this regulation and subsequent improper disposal of waste can land you in hot water with the EPA, and can lead to fines if it's found you are out of compliance. In addition, waste that fits under this regulation is typically designated for special processing to recover the metals in that waste, and your business could benefit from certain compliance incentives if you can show the EPA that you're properly dealing with this waste.

Here are some other processes that aren't electroplating by some definitions, but still generate waste which falls under the umbrella of F006:

- Alkaline Surface Cleaning

- Zinc Plating on Carbon Steel using Cyanides

- Zinc Plating on Gray Cast Iron

- Iron Plating on Aluminum

- PreCleaning activities prior to the electroplating process

- Ion-exchange resins from rinsewater treatment (assuming F006 precursor)

- Photoresist Stripping

- Cleaning and Stripping in the printing industry

- Bright Dipping

- Silicon water etching

- Spent Activated Carbon from rinse water treatment (assuming F006 precursor)

If any of these processes occur onsite and the wastewater from the process is treated in a wastewater treatment system, then sludge from this treatment would be regulated under F006. Whether or not you can characterize your waste as F006 will determine how much you can keep onsite at a time, how you are required to dispose of this waste, and what kinds of provisions you are required to implement in order to stay compliant, like an additional level of pollution control or waste processing, for example. Proper characterization of your waste also helps your receiving facility deal with it in a way that is safe and environmentally conscious, ensuring they will continue to accept your waste rather than rejecting it because it hasn't been properly characterized.

As a general rule of thumb, it is always better to over-code your waste system than risk overlooking an important regulation for a specific type of waste. One way to ensure compliance without completely restructuring your waste management plan is to minimize or eliminate generation of F006 if at all possible. A couple of ideas for minimizing or eliminating your F006 waste and being able to bypass these regulations are:

- Cleaning and drying your electroplated or etched components in a separate step to eliminate contaminants being carried into the wastewater treatment system.

- If your company only generates low levels of these contaminants, you might be eligible to get your F006 de-listed or the requirement for 'timely removal' eased.

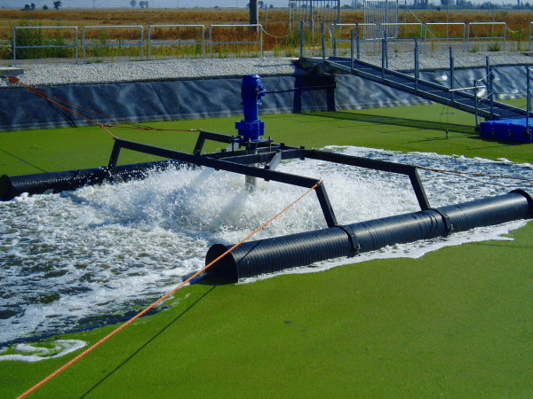

Click the link below to learn more about how we can help you achieve 100% wastewater compliance.

.png)