Plastics Recycling: By The Numbers

If you are looking to pursue a successful recycling program or enhance an existing one, it will help to understand the types of plastics involved in order to maximize sustainability and ROI in this endeavor. Some plastic polymers are more amenable to volume recycling than others, so the key to a proficient, high-yielding recycling program is understanding favorable plastic polymers for the recycling program you utilize.

Rolling out a successful plastics recycling program is a great way to hit overall organizational sustainability targets. As with any initiative, there are special factors that affect a plastics recycling program’s success—a key one being plastic type sent for recycling. Analysis and prioritization of the plastic types that will yield the greatest volumes of recycled materials is crucial to take full advantage of recycling efforts.

Managers can maximize benefits and justify the time, effort, and resources involved in implementing plastic waste recycling programs by focusing on the most recyclable plastics that their organizations generate or use.

Sustainability Goals Are Crucial

The pressure for businesses to promote sustainability, placed by governments and environmental organizations worldwide, isn’t going away anytime soon—if ever. Nations continue to form agreements that force businesses to change their sustainability strategy into the future—many of which will likely become mandates, introducing the threat of non-compliance charges to companies that lack sustainability programs.

On top of this, consumers worldwide are demanding plastics sustainability from the businesses they patronize—in 2021, for example, 32% of consumers indicated that they would prefer to do business with companies actively reducing their environmental impact.

Going green is becoming a self-defense mechanism for market protection. The market as a whole is making it clear that commerce will be limited to sustainability-focused organizations. Businesses that don’t actively pursue sustainability risk losing market share to those rivals that are environmentally friendly.

Plastics Recycling: Road to Sustainability

Given these drivers, businesses are turning to recycling their plastics as a logical way to meet sustainability goals. Plastic recycling is a proven and sensible way for organizations to meet their sustainability goals, in part because plastics are environmentally and economically expensive throughout their entire lifecycle, from origination to disposal, and recycling helps lessen the impact of plastic waste on the environment.

There are multiple sustainability benefits to proper plastic waste disposal. Efficient recycling can:

- Reduce greenhouse gas emissions

- Cut oil consumption

- Eliminate the need for mining and ecosystem destruction

- Contribute to more sustainable and eco-friendly operations overall

On top of this, efficient recycling can even save an organization money and help support improved overall operational ROI. Failure to integrate a realistic plastics waste recycling program into corporate sustainability initiatives, on the other hand, is a big negative. Inefficient and unmet recycling goals will hurt not only the environment—but your facilities and operations as well.

Successful Plastics Recycling: The Challenge

This is not to underestimate the hurdles to a fully successful plastics recycling program. Such initiatives are difficult to execute—largely because of the many restrictions regarding which specific polymers can be repurposed after recycling has occurred. Polystyrene, for example, is often used in medical and food service applications (test tubes, egg carton, and petri dishes, etc.) but can rarely, if ever, be recycled as municipal solid waste (MSW).

Another example is polypropylene (PP), which is widely used as a packaging material in plastic bottles, containers, and medical devices but is difficult to recycle in traditional streams and turns an “undesirable” color throughout the process. These factors result in recycling of only between 1-3% of PP in traditional United States plastics recycling systems

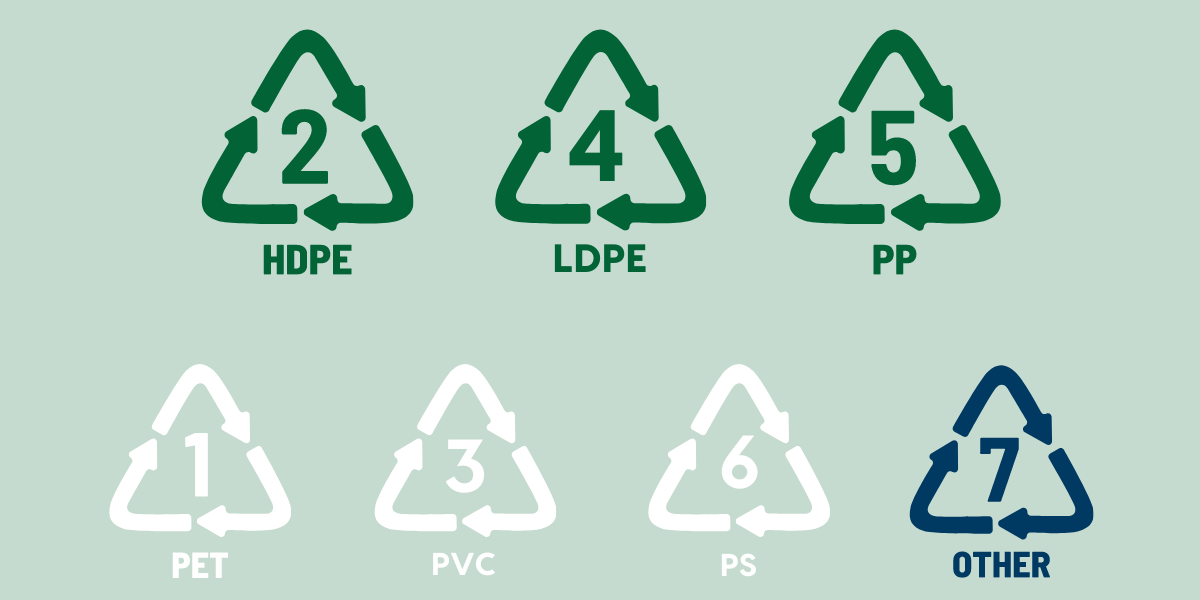

In 1988, the Plastics Industry Association (PLASTICS) devised a numbering system to indicate the type of polymer that each plastic product is made of. They invented a scale that ranges from numbers 1 through 7—plastic products labeled as 1 and 2 tend to be more recyclable in traditional systems, while the rest are, with a few exceptions, typically more difficult.

Of course, this will vary depending on the end-management you chose for your plastic wastes—to fully optimize a plastics recycling program and maximize ROI potential, compliance, overall brand image, and sustainability, it’s key to consider the most- and least-preferred types of plastics of the recycling system you choose.

BestPLUS: Plastics By The Numbers

A major option for industrial plastics is to partner with a vendor that can volume-recycle these wastes into something useful—like Best Plastic Lumber US (BestPLUS), a subsidiary of Triumvirate Environmental. BestPLUS recycles many different types of plastics—including traditionally hard-to-recycle wastes—into durable plastic lumber.

While almost every generated plastic waste can be recycled with BestPLUS, there are some plastic numbers that are preferred by the facility. Below, we will explore some of the most- and least-favorable plastic types for this program—ensuring your sustainability programs are as beneficial and efficient as possible. Compared to what can and can’t be recycled as traditional MSW, the numbers might surprise you.

#1: Polyethylene Terephthalate (PET)

Traditionally used in plastic bottles, bakery products, and cosmetics, it is difficult for BestPLUS to recycle these tough and water-resistant plastics. Difficulties in breaking down these polymers make it hard to resize the plastic into something suitable for lumber applications. Also, the melting point is too high to be compatible with other materials involved in the lumber creation process.

#2: High-Density Polyethylene (HDPE)

Commonly found in industrial settings in pallets, drums, medicine bottles, and more, HDPE is ideal for recycling with BestPLUS. This is due to its impact resistance and strength-density ratio—this plastic is easily manipulated during the lumber manufacturing process.

#3: Polyvinyl Chloride (PVC)

Used in applications like piping, industrial flooring, and sports equipment, PVC has a high chlorine content and contains hazardous additives that make it hard to recycle by the BestPLUS team.

#4: Low Density Polyethylene (LDPE)

LDPE plastic products—including stretch wrap, garbage bags, and recycling bins—typically can’t be recycled in common systems but can easily be recycled by the BestPLUS team. LDPE has a reasonable temperature resistance and is compatible with other materials recycled in the BestPLUS process.

#5: Polypropylene (PP)

PP, as is used in pipette tips, bottle caps, and straws, is not widely and easily recycled in MSW systems but is ideal for BestPLUS recycling. Its low density and high heat resistance are ideal for this, and it is compatible with other materials often recycled with BestPLUS. PP is also non-toxic, lightweight, and adaptable, which supports its widespread use after recycling.

#6: Polystyrene (PS)

Medical test tubes, petri dishes, and take out containers are typically made with PS. These are unfavorable in both traditional MSW recycling systems and by BestPLUS because most PS products are very lightweight, often contaminated with food, and incompatible with other lumber materials—which often results in difficulty processing this material.

#7: Other

Number 7 plastics can be either a combination of plastic types 1 to 6 or a different material type altogether. As such, recyclability can vary—facility testing can determine the fit and recyclability of each specific plastic product.

Optimize Your Plastics Recycling

Of course, though recycling may be difficult for certain plastic polymers, it is never impossible—especially with BestPLUS and Triumvirate Environmental, that have recycling solutions for even the most resistant wastes.

No matter what plastics recycling vendor you partner with, it is important to understand the preferred plastics that can be recycled within their systems in order to optimize your recycling. By prioritizing these plastics for recycling over others, you can obtain the most efficient system—and your ROI and environmental impact will thank you.

Interested in learning more about Triumvirate Environmental’s and BestPLUS’s recycling capabilities? Contact us today, or read more by clicking the button below.